hardness test report mech210l|rockwell hardness test lab report : trade The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an . web9 de ago. de 2023 · Avaliamos Gratorama Casino completamente e atribuímos um Índice de Segurança abaixo da média .Este casino tem algumas boas qualidades, mas também .

{plog:ftitle_list}

webFruit Party – Jogar Grátis. 4.5. Nossas classificações. Revisão verificada. Provedoras. 4. Gráficos. 5. Bônus. 4. 20Bet Casino 4.1 Avaliação do 20Bet Casino. Bônus em .

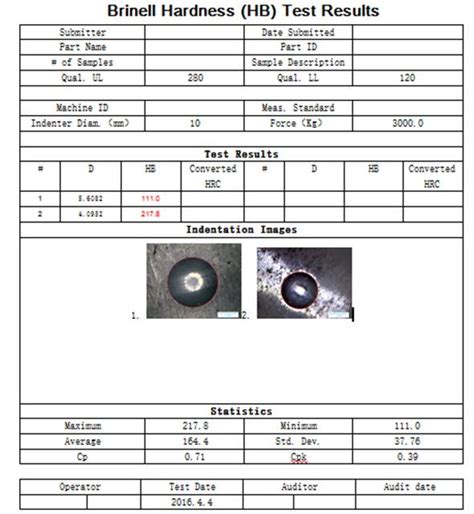

The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an .Efforts to find the hardness of steel, aluminum and brass, by means of the Brinell and Rockwell Hardness tester, generated the results shown in Fig. 1 and Fig. .

Brinell Hardness Test; For Brinell hardness test. The hardness of materials are test by pressing a steel ball or tungsten carbide ball for a time of 10 to 15 seconds into the surface of specimen by a standard load F [kgf]. After that, the .PDF | On Oct 14, 2019, D.B.Naga Muruga published Hardness Test Report | Find, read and cite all the research you need on ResearchGate In this report, the mass effect on the pressing force in Shore hardness test was investigated. The experiment was carried out with a Shore scleroscope of D-type on five specimens which were .

(III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.Hardening tempered parts

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

View Hardness Testing Lab.docx from MECH 2335 at CUNY New York City College of Technology. Course No.: MECH 2322 Name: Latanya Nelson Section No.: DL220 Professor: A. Rahman REPORT FOLDER _ NEW YORKHardening tempered parts 🚰 Method 2: Read Your Water Quality Report. Public water systems must all produce annual Water Quality Reports (otherwise called Consumer Confidence Reports) to document the contaminants detected in their treated municipal water supplies.. If you don’t want to pay for a hard water test, you can simply review your latest Water Quality Report for your local water .

The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material. This hardness test is preferred because it is simple, easy and relatively nondestructive .

Knoop Hardness Test: The Knoop hardness testing measures the hardness of small and delicate materials, thin sections, and coatings. These test methods employ a rhombic-based diamond probe. The elongated shape allows for a precise diamond-shaped indentation on small, narrow surfaces. HK = (1.854 × F) / (I2) HK is the Knoop hardness valueThe Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .Hardness Test 2/5 the microscope is in millimeters. The larger diameter indentation corresponds to a softer material and lower Brinell number. VICKERS HARDNESS TEST The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degreesThe Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically. Used for materials with a coarse or inhomogeneous grain .

PDF | On Aug 27, 2023, Dokta Urame published EN113 Lab 02 Brinell Hardness Testing Report | Find, read and cite all the research you need on ResearchGate

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .As part of the first lab, Brinell Hardness test will be used to determine the level of hardness applied from a 10 mm steel ball indenter onto a steel and. Skip to document. University; High School. . Lab Report BRINELL HARDNESS .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work.

When hardness testing of welds, a series of measurements are made in a given pattern at a specific distance from the sample edge or top of the weld. The progression of the hardness values can then be plotted in a graph. Methods typically used: HV5 and HV10 ; Applicable standards: ISO 9015-1/-2 ;

9. Perform tensile test, hardness test, and impact test of materials 10. Perform differential thermal analysis of materials 11. Prepare samples for microscopic examination 12. Know the fundamentals of fracture mechanics 13. Describe electrochemical corrosion and .

View Lab Report #6.pdf from MECH 210L at California State University, Chico. Organizational/Quality: _/_ Calculation/Results: _/_ Data: _/_ TOTAL: _/_ Strain Hardening Test MECH 210L-01 Materials AI Chat with PDFHardness Testing Quang Nguyen School of Engineering Grand Valley State University Laboratory Module 4 EGR 250 Material Science Engineering Section 902 Instructor: Professor Lindsay Corneal October 27, 2016 Abstract The purpose of this experiment were to utilize the hardness as an index of mechanical properties to relate the mechanical properties of ferrous .Quiz yourself with questions and answers for MECH 210L Final, so you can be ready for test day. Explore quizzes and practice tests created by teachers and students or create one from your course material. . Create. Log in. Test: MECH 210L Final. Name: Score: 28 Multiple choice questions. Definition. Hardness is the resistance of a material to .

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation. The precipitation kinetics of 2519A aluminum alloy after different cold rolling reductions before aging was investigated by hardness test and differential scanning calorimetry (DSC).Vickers hardness testing of small areas. A u: t o m a t i c e d i m e n s i o n s i b y A V P A K . Software that supports control, testing, and report creation related to : hardness testing Supports parameter setting and automatic measurement. Compatible with Windows 7 Professional 32-bit

View Lab - report 1 (Vickers Hardness Test).docx from BMM 1511 at University of Malaysia, Pahang. BMM1511 Engineering Mechanics Lab 1 Lab E1 Vickers Hardness Test Section/Group Section 02 Group

rockwell hardness test lab report

moisture meter for cannibis

moisture meter for carton

webNunchucks Chicken slot machine by Skywind Studios. Enjoy Nunchucks Chicken online slot with Bonus and Free Spin

hardness test report mech210l|rockwell hardness test lab report